Keeping wet ash removal conveyor running at UK’s first straw-fuelled biomass plant

Summary

Elean power station, owned by Melton Renewable Energy, was the first straw-fired biomass plant to be built in the UK. At the time of completion in 2000, its 38 MW capacity also made it the largest of its kind in […]

Elean power station, owned by Melton Renewable Energy, was the first straw-fired biomass plant to be built in the UK. At the time of completion in 2000, its 38 MW capacity also made it the largest of its kind in the world. 20 years later, Elean power station still serves as a model of sustainable power generation.

EPR Ely, the company responsible for operating the Elean power station, initially contacted FB Chain in 2012 for help with the wet ash conveyor, which as not performing as well as it should. Ash removal is a demanding application wet or dry, but wet ash removal is a particular challenge due to the damp, corrosive environment.

Corrosion-resistant components

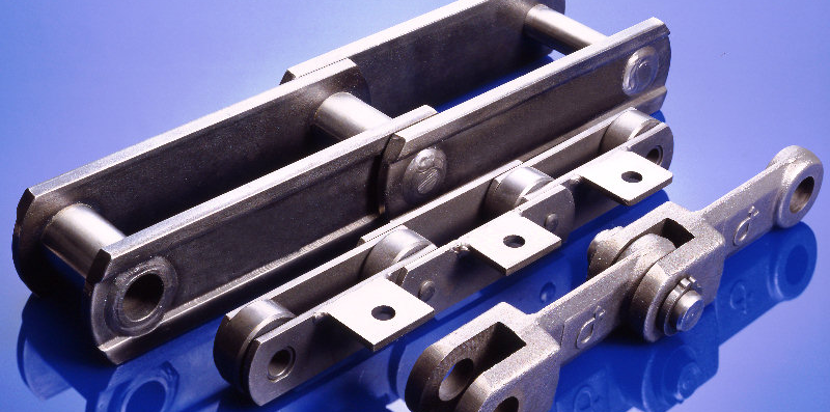

Our first step was to install some of our FB corrosion-resistant conveyor chain and sprockets, which immediately boosted the performance of the conveyor. However, there was still room for improvement.

Working closely with EPR, we introduced a number of tweaks to the design of the wet ash removal chain and sprockets – increasing the size of the outer plates, welding the pins, and changing the material of the pins and bushes and sprockets. This greatly improved the components’ resistance to wear, pitting and corrosion, and the cost savings to the facility for this conveyor alone are well into the seven figures.

No unscheduled downtime

The application is now more stable, downtime occurs only when scheduled, and the consistency of power supply can be better maintained. Unscheduled downtime is a huge problem for any power station and the generation of consistent power is paramount.

Our relationship with EPR Ely has grown over the last eight years based on an understanding of continuous improvement. We are constantly working together to find ways to maximise efficiency, achieving the greatest number of working hours without unscheduled downtime.

Relationships are key

We are proud to have played a role in keeping Elean power station working at its optimum and are grateful for EPR Ely’s trust and collaboration in developing these best practices for the biomass industry.

As leading independent generators of renewable energy in the UK, EPR and Melton Renewable Energy understand the importance of supplier relationships in the day-to-day running and long-term operating capability of their equipment. Optimising and maintaining equipment is crucial to ensuring consistent energy supply.

John Wallis, part of the maintenance team at EPR Ely said: “I have worked with FB Chain since the beginning and look forward to continuing our relationship and improving the facility.”

Discover more about improving the service life of wet ash removal chains or get in touch to discuss how we can optimise your biomass conveyor.

Topics: Conveyor chain, Biomass, WetAshRemoval